Technology Empowerment, Intelligent Manufacturing for the Future|Xi'an Intelligent Remanufacturing Research Institute Assists Shennan Tianyi in Achieving High-Standard Remanufacturing of Hydraulic Support Cylinders

Since entering the fourth quarter, Shaanxi Shennan Tianyi Equipment Manufacturing Co., Ltd. has closely adhered to the "four operational philosophies," coordinating efforts across three key fronts—safety management, production operations, and cost reduction with efficiency enhancement—to continuously advance the high-quality development of mining equipment remanufacturing. As an industrial base jointly established by Shaanxi Tianyuan Intelligent Remanufacturing Co., Ltd. and Shennan Industrial Development Co., Ltd. of Shaanxi Coal Group, the company focuses on remanufacturing and high-end equipment manufacturing. Leveraging the in-depth application of intelligent remanufacturing equipment and processes, it has gradually evolved into a model for transitioning from labor-intensive to technology-intensive manufacturing in the Shennan region.

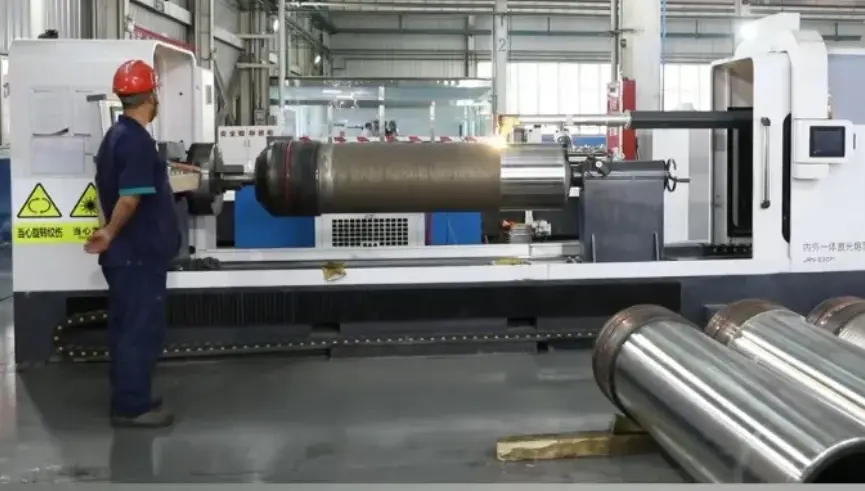

In this transformation, Xi'an Intelligent Remanufacturing Research Institute provided critical technical support to Shennan Tianyi. The institute’s independently developed advanced laser cladding equipment and process system enabled Shennan Tianyi to efficiently and high-quality complete the remanufacturing of 160 sets of 7.5-meter hydraulic support cylinders for the Shaanxi Nonferrous Hanglaibay Project. This not only improved the efficiency and quality of the remanufacturing process but also injected robust technological momentum into the green and intelligent upgrading of mining equipment.

Hydraulic supports, as the core equipment of mine support systems, operate under harsh conditions such as high pressure, heavy loads, and strong corrosion. Their cylinders are prone to wear, corrosion, and seal failures. Traditional repair processes often face challenges such as complex structures, low repair accuracy, susceptibility to deformation, and insufficient wear resistance, making it difficult to meet the demands of efficient and highly reliable remanufacturing. To address this, Xi'an Intelligent Remanufacturing Research Institute tailored a multi-model laser cladding equipment portfolio for Shennan Tianyi, covering full-scenario applications from on-site repairs to production line integration.

The mobile cladding equipment, equipped with a tracked chassis and a six-axis robot, can move flexibly within the factory, enabling multi-station operation with a single device, cross-line and cross-area collaborative work, and on-site repair of large workpieces. This not only saves labor and reduces hoisting and transfer time but also integrates additive and subtractive processes to optimize workflows.

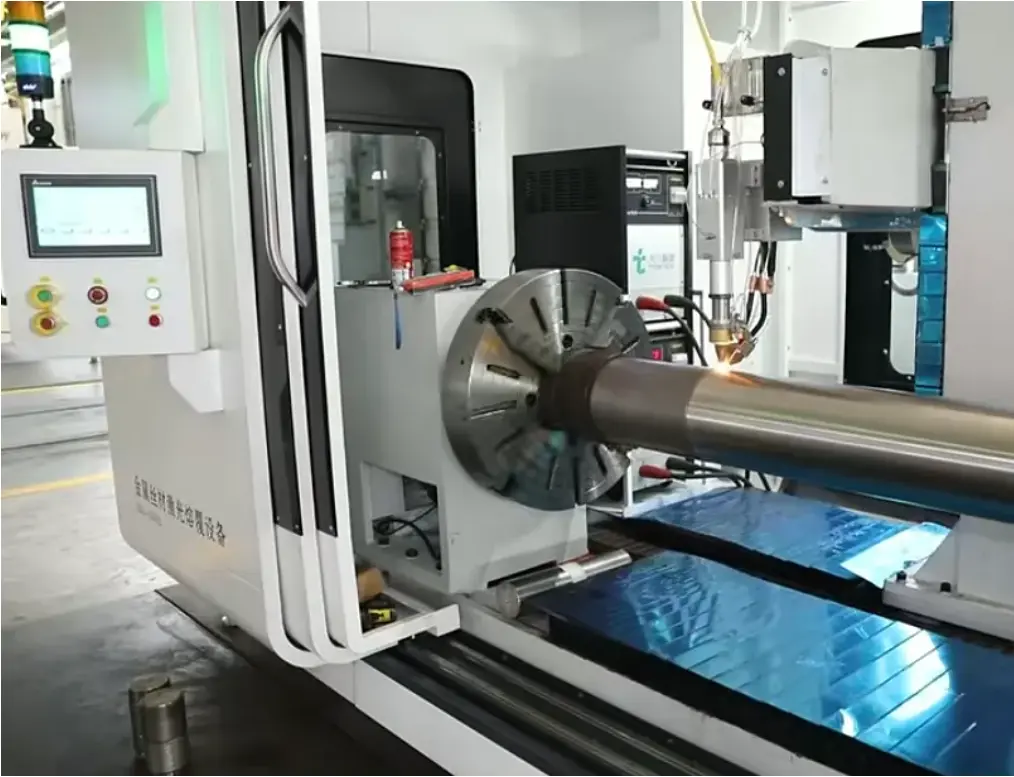

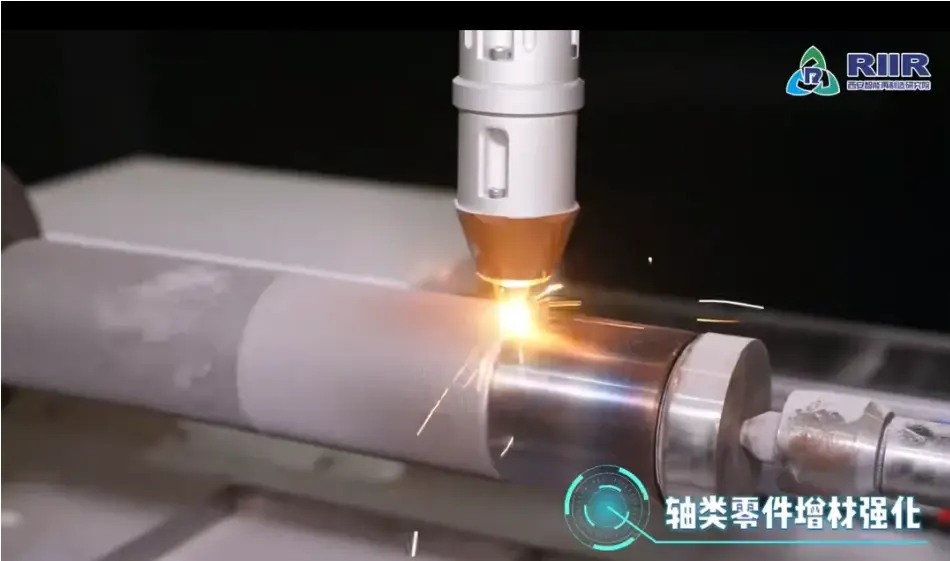

The wire-fed laser cladding equipment is specifically designed for anti-corrosion and wear-resistant cladding on the outer walls of components such as shafts, cylinders, and pipes. Through a newly designed laser cladding head, optimized optical path, added wire feeding module, and upgraded control system, it achieves coaxial laser wire feeding, significantly improving material utilization and cladding efficiency while reducing heat input during the cladding process. It is particularly suitable for precision remanufacturing scenarios that are sensitive to material costs and require stringent mechanical performance. The equipment features built-in intelligent process parameter packages, is easy to operate, and significantly enhances production consistency and efficiency.

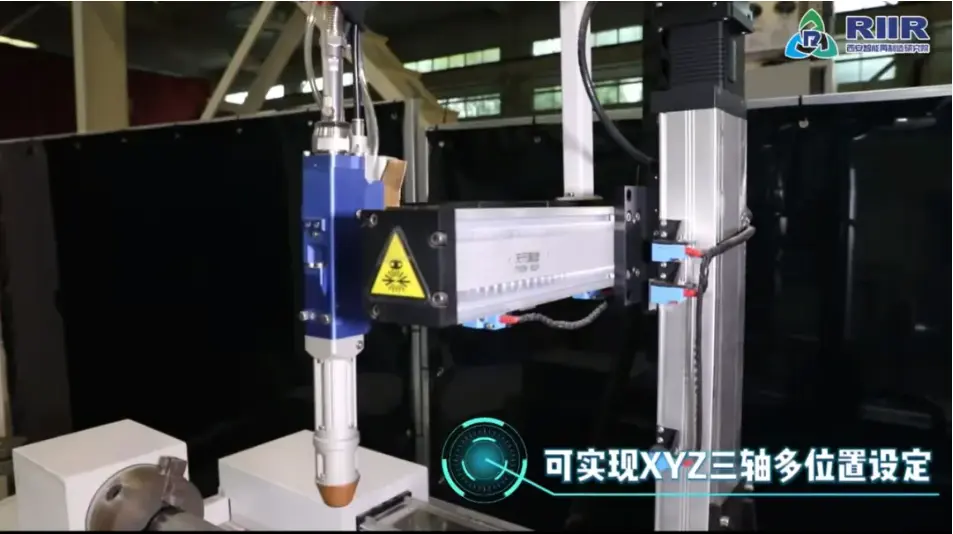

The portable laser cladding device adopts an integrated compact design, with a lightweight body that supports flexible movement and rapid deployment. It incorporates intelligent parameter algorithms and a process database, supports one-click start/stop, and has a low operational threshold. Additionally, the device can be adapted to various motion mechanisms such as lathes and robotic arms to achieve automated cladding, making it especially suitable for on-site repairs and multi-station collaborative operations.

The internal-external integrated laser cladding equipment, independently developed by the institute, represents a comprehensive laser cladding solution for all scenarios, achieving a significant breakthrough in internal wall cladding technology. It meets the high-quality cladding requirements for complex internal wall structures such as through-holes and blind holes. The cladding layers excel in key indicators such as density, hardness, and corrosion resistance, reaching industry-leading standards. This technology effectively addresses traditional challenges in internal hole cladding, such as excessive heat generation, unstable processing, and short operation durations. With dual functionality for both internal and external wall cladding, it significantly enhances equipment utilization and process coverage.

Shennan Tianyi has established a closed-loop quality control system covering the entire process of "disassembly—repair—assembly—debugging." Supported by the institute’s equipment and processes, the company has achieved a 40% improvement in cylinder repair efficiency, significantly shortened delivery cycles, and enhanced the bonding strength between cladding materials and substrates. The wear and corrosion resistance of the repaired components surpass that of new products, resulting in significant cost savings and embodying the principle of "repairing the old to outperform the new" while promoting resource recycling.

This collaboration is not merely an extension of equipment supply and demand but a deep practice of technological integration and model innovation. Moving forward, Xi'an Intelligent Remanufacturing Research Institute will continue to collaborate with Shennan Tianyi to advance mining equipment remanufacturing toward greener, smarter, and higher-end solutions. The institute aims to provide customers with more scenario-based remanufacturing value, enhancing their market competitiveness and sustainable development capabilities. In the future, Xi'an Intelligent Remanufacturing Research Institute will persistently develop a digital platform for "AI + Remanufacturing" to drive the transformation of manufacturing from labor-intensive to technology-intensive. Through end-to-end solutions, it will achieve goals of efficiency improvement, cost reduction, and high-quality development in the manufacturing sector.