Solutions

Full-stack Intelligent Remanufacturing solutions

The Intelligent Remanufacturing Equipment Holistic Solution is an integrated system encompassing R&D, design, production, integration, and service. It provides end-to-end equipment support and technical assurance for customers, covering the entire process from waste product recycling and inspection to remanufactured product delivery. This solution helps clients establish complete, efficient, and intelligent remanufacturing production lines, enhancing product quality and performance, shortening production cycles, reducing operational costs, and strengthening market competitiveness.

The overall plan is generally composed of the following six sections:

1. Intelligent disassembly

Intelligent disassembly serves as the foundational component of our company's integrated smart remanufacturing solution, designed to achieve efficient, precise, and eco-friendly automated dismantling of end-of-life products. This process delivers high-quality reusable components for subsequent remanufacturing stages. By leveraging intelligent automation and IoT sensing technologies, it effectively addresses key challenges in traditional disassembly methods—including low efficiency, high costs, insufficient precision, and heavy reliance on manual labor.

2. Intelligent Detection

Intelligent detection undertakes the disassembly process of waste parts, and quantitatively evaluates the geometric dimensions, surface defects, internal structure and other key indicators of parts through high-precision and automated detection technology, providing data support for subsequent remanufacturing process decisions (such as repair, reprocessing or scrap).

3. Intelligent composite additive manufacturing

The intelligent composite additive manufacturing process serves as the core component of the smart remanufacturing solution. By integrating advanced additive manufacturing technologies with intelligent systems, it enables precise repair and performance enhancement of damaged or failed components. This process overcomes the limitations of traditional repair techniques in adapting to complex geometries, matching material properties, and controlling repair accuracy.

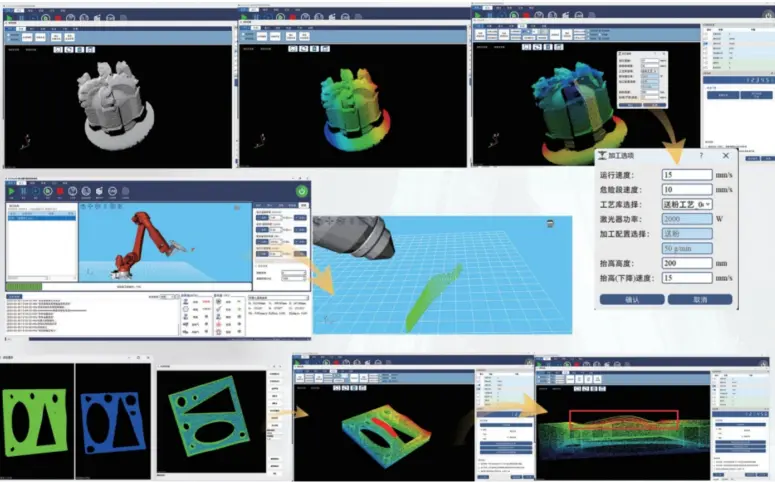

Intelligent additive repair software

The intelligent additive repair software integrates multiple functions including unit debugging, processing task queue management, process database, path twin, status monitoring, and parameter management. With robust graphic processing capabilities, it supports various processing input methods such as standard teaching trajectories, parametric trajectory libraries, 2D graphic imports, 3D model-driven operations, and model-free 3D reverse reconstruction. The system enables rapid additive manufacturing and repair remanufacturing without programming, combining high precision, efficiency, and user-friendliness.

4. Intelligent Composite welding

Intelligent Composite welding effectively addresses the limitations of traditional manual and semi-automatic welding, which often rely heavily on operator expertise, suffer from inconsistent quality, and exhibit high defect rates. By automating the welding process and implementing intelligent path planning, this technology significantly reduces human intervention. As a result, remanufactured products can achieve or even surpass the performance of new products in critical metrics like mechanical strength and durability. Not only does it shorten welding time per unit, but it also minimizes rework caused by human factors, ultimately boosting overall production line efficiency.

5. Intelligent subtractive

The intelligent material removal process serves as a critical juncture in the remanufacturing system, bridging upstream preprocessing with downstream additive manufacturing. This dual-core function operates through two key mechanisms: First, it precisely removes surface fatigue layers, corrosion layers, and damaged areas from decommissioned components, restoring their geometric dimensions and surface quality to create a qualified base material for subsequent intelligent additive repair or reuse. Second, after completing intelligent additive manufacturing (e.g., 3D printing) or smart welding repairs, it performs precision shaping on excess material buildup, weld bead height, and heat-affected zones. This ensures final dimensional tolerances, form-shape accuracy, and surface roughness meet both design specifications and performance standards for remanufactured parts, providing essential safeguards for quality control and performance enhancement in remanufactured components.

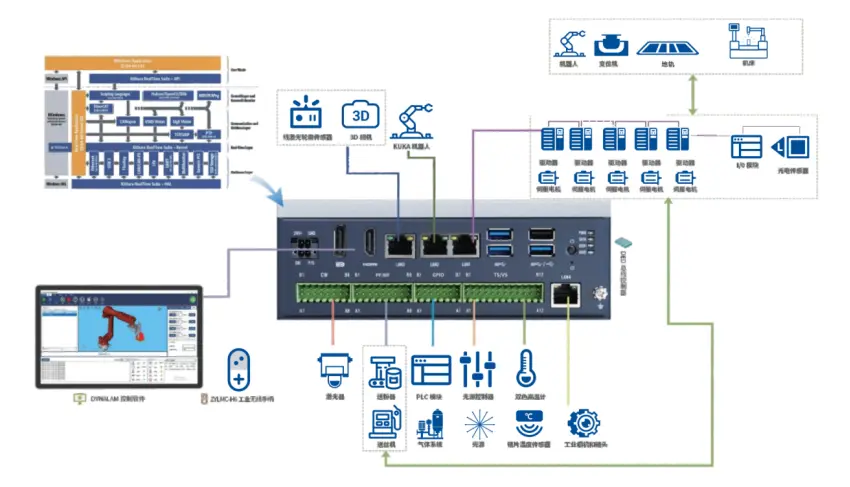

VI. Intelligent remanufacturing control system

By integrating industrial inspection, reverse engineering, and smart manufacturing technologies through production data capture, we have established a comprehensive technical framework spanning "visual recognition, model reconstruction, path planning, and additive repair". This system drives AI-assisted optimization of production processes, repair strategies, defect control, and process innovation. It provides reliable technical support for high-end manufacturing sectors including energy, aerospace, rail transit, and defense industries, accelerating industrial intelligent transformation.

The whole-link system of remanufacturing is realized by highly integrated control

In summary, we can fully customize tailored solutions for customers by flexibly combining six core modules based on their specific needs, product characteristics, and production scale. Through our professional R&D team and production base, we develop and manufacture core equipment while providing system integration services. Additionally, we offer comprehensive technical training for operators, technicians, and managers to ensure seamless coordination of equipment systems and smooth execution of related tasks.

VII. Relevant Cases

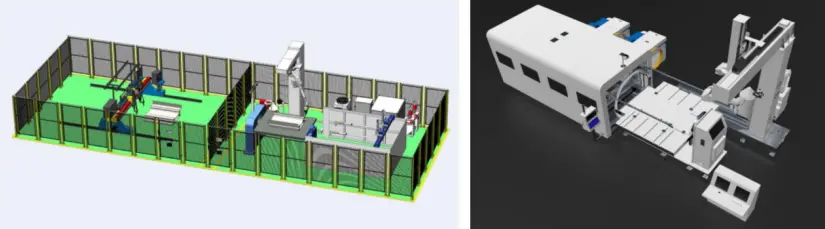

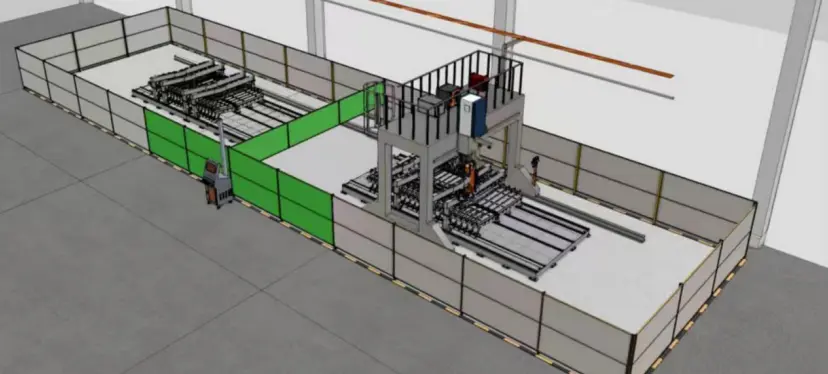

1. Intelligent remanufacturing line for conveyor trough

According to the characteristics of the product, laser cladding, cold metal transition welding, vision system and intelligent control technology are comprehensively adopted to build intelligent remanufacturing production line.

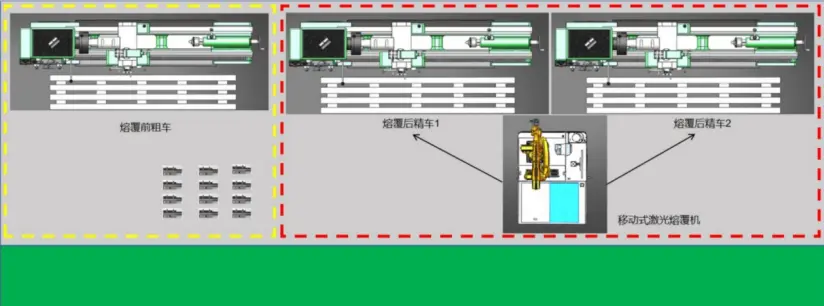

2. Crosshead intelligent remanufacturing production line

According to the characteristics of products and customer capacity requirements, optimize the processing technology and production beat of products, design the automatic additive and subtractive production line, and realize the automatic production of products.

3. Intelligent composite welding workstation for EMU car body

According to the product requirements, laser arc composite welding technology is adopted to design robot and gantry mechanism equipment to replace manual operation, so as to realize continuous and efficient automatic production operation, and the welding effect is more stable and reliable.

4. Intelligent material production line for guide shoes

In accordance with the manufacturing requirements of guide shoes, ensure the maintenance quality and production efficiency of guide shoes, and establish an intelligent production line for the welding and grinding of guide shoes.