Intelligent detection solution

Intelligent detection solution

gave an outline of

To address the complex inspection requirements of various components, we leverage non-contact machine vision, high-precision laser sensors, multimodal data fusion algorithms, and automated robotic platforms. By integrating intelligent sorting algorithms and traceable data systems, we overcome challenges in remanufacturing such as quantifying damage in old parts, optimizing repair processes, and ensuring quality consistency. This establishes a closed-loop quality control system for the entire remanufacturing process, providing intelligent and digital inspection solutions for advanced equipment manufacturing.

research area

1. Non-contact precision measurement and high precision sensing coupling technology

2.2 Quantitative Analysis of Data Fusion Defects in 2D and 3D Camera Systems

3. Complex inner wall environment adaptive detection and pipeline robot system

4. High precision inner diameter detection sensor and algorithm optimization

Intelligent detection equipment

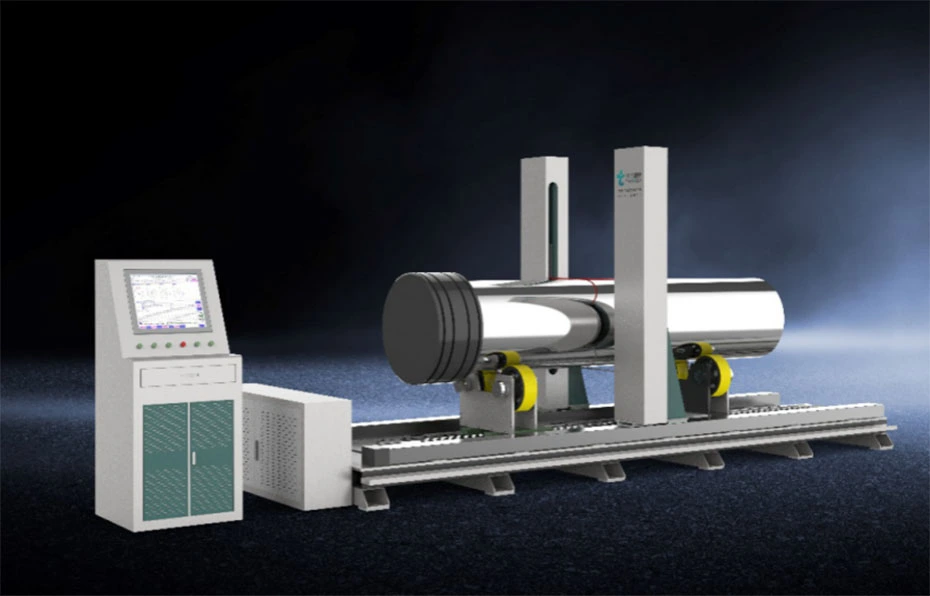

— Intelligent shaft diameter optical measurement equipment

Realize the coupling technology of automatic edge detection system and high-precision displacement sensor system

±0.01mm precision for rapid online measurement with synchronized traceable data chain generation

— Intelligent interior wall defect detection equipment / laser inner diameter detection equipment

The robot is equipped with 2D/3D fusion imaging technology and high-precision displacement sensor to identify 0.5*0.5*0.05mm-level defect morphology, accurately locate damage, quantify defect size and depth information, and achieve high-precision inner diameter measurement of ±0.02mm.