Aisa Potash Tyontech

Enterprise profile

Aisa Potash Tyontech Intelligent Manufacturing Co., Ltd. (abbreviated as "Aisa Potash Tyontech"), located in the Aisa Potash International Smart Industrial Park in Laos, is a high-tech enterprise jointly established by Aisa Potash International and Tyontech Intelligent Manufacturing. Specializing in the remanufacturing of mining equipment, the company focuses on reshaping the lifecycle value of equipment. It provides maintenance, remanufacturing, and product leasing services for mining, mineral processing, and deep-processing equipment, dedicated to promoting efficient industrial resource recycling and sustainable development.

By the end of October 2024, the first phase of the project has been completed, covering an area of 5000 square meters, equipped with more than 50 sets of advanced equipment, and covering the service area of Laos and Southeast Asia, helping mining and chemical enterprises to reduce costs and increase efficiency.

Core technology

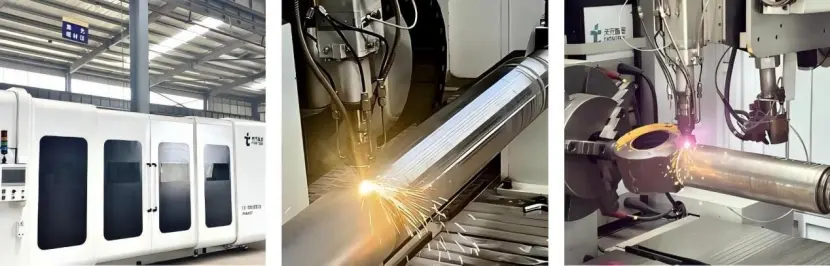

It covers cutting-edge technologies such as failure analysis, additive manufacturing and intelligent welding. It has more than 50 sets of advanced equipment, such as laser additive work station (12000W super power), 50-ton hydraulic disassembly equipment and high-precision CNC machine tools, to carry out whole-process quality control of products to ensure product quality.

1. Failure analysis and reverse engineering

Precise analysis of equipment failure status and cause, reconstruction of design and application of new materials, improve equipment performance and prolong service life.

2. Additive Manufacturing

The realization of complex heterogeneous workpiece repair and functional gradient material cladding can not only restore the size of the workpiece, but also strengthen the corrosion and wear resistance of the workpiece.

3. Upgrade and Remanufacture

Through reverse design and the application of new materials, the performance of equipment is reshaped, and the equipment or workpiece is endowed with a new use cycle of "repairing the old to surpass the new", so as to reduce the equipment use cost and realize cost reduction and efficiency increase.

4. Testing and Trials

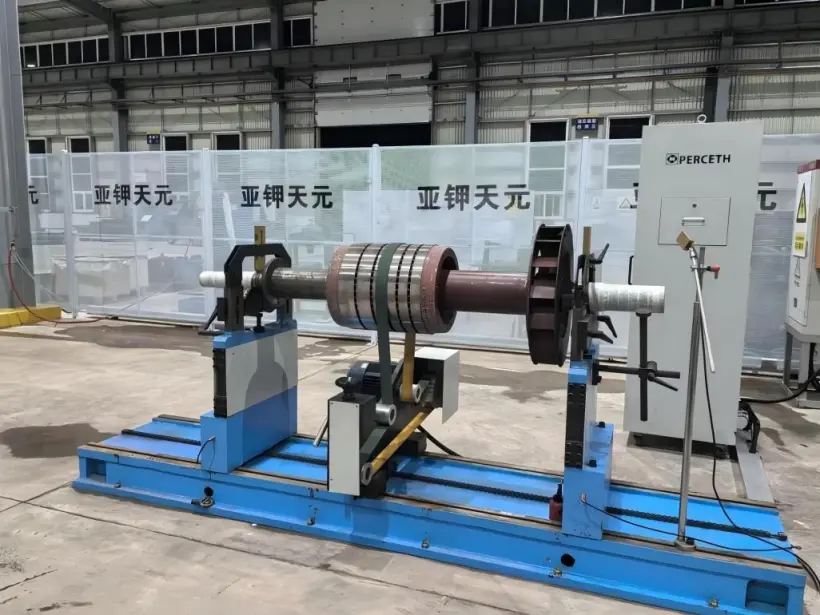

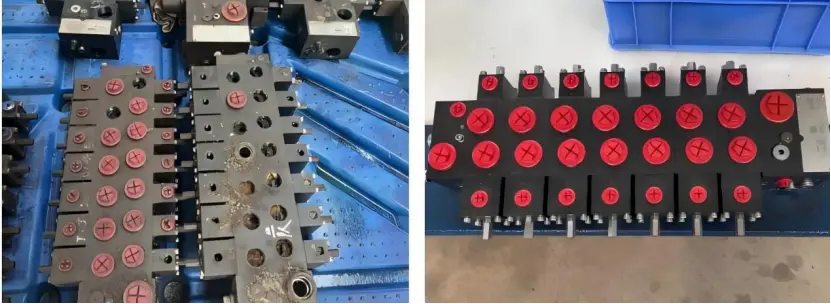

The performance of the equipment is guaranteed by motor dynamic balance, dielectric strength, no-load test, hydraulic component pressure resistance, leakage and other tests.

Device Display

· Laser additive work station ·

· Heavy CNC machine tools ·

· Hydraulic testing equipment ·

· Cylinder test equipment ·

· Motor inspection equipment ·

·Dynamic Balance Tester ·

Core business

Our services encompass maintenance and remanufacturing of motors, hydraulic transmission components, and complete equipment systems. We provide comprehensive solutions including product failure analysis, reverse engineering, application of new technologies and materials, and a full-process quality inspection system. This ensures that remanufactured products meet or exceed new product standards, supporting industrial enterprises in resource recycling and achieving cost reduction and efficiency enhancement.

1. Motor category

We provide comprehensive maintenance and upgrade services for high-voltage and low-voltage motors, transformers, and submersible pumps. Through rotor dynamic balancing calibration, insulation reinforcement, and protection rating upgrades, we ensure the repaired motors achieve or exceed the performance of new units.

2. Hydraulic transmission components

The repair and remanufacturing of transmission components such as hydraulic cylinders, motors, pumps, valve assemblies, and reducers restores the workpiece's functionality. For example, laser cladding with new materials on scratched or corroded piston rods not only restores their dimensions but also enhances surface hardness and corrosion resistance.

· Cylinder repair before and after comparison ·

· Comparison of valve group maintenance before and after ·

3. Complete Equipment

The overhaul of the whole mining equipment and the reinforcement and repair of the structural parts fundamentally solve the various problems accumulated by the long-term operation of the equipment, fully restore the performance and accuracy of the equipment, and prolong the service life of the equipment.