- Product Description

Product Overview

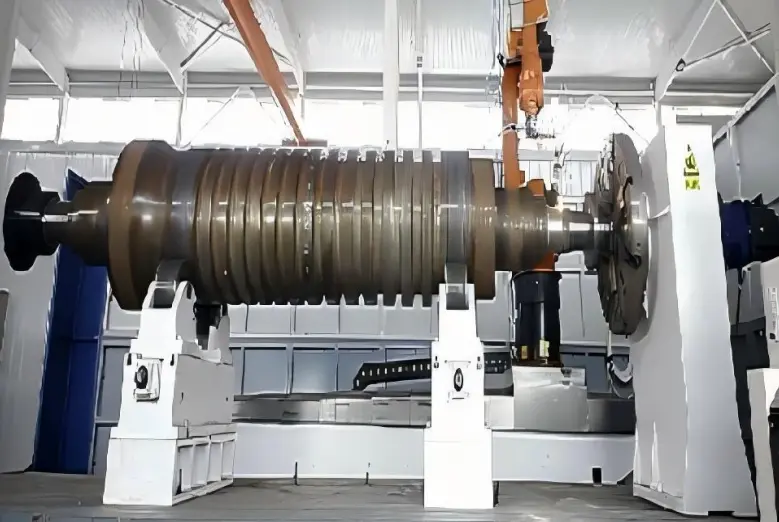

The sealing and bearing positions of TRT main shafts are prone to wear during prolonged operation. By employing additive-subtractive composite manufacturing technology, this process achieves defect removal through subtractive machining, dimensional adjustment via additive repair, and precision restoration through finishing. The entire workflow is completed in a single operation on an additive-subtractive composite machine tool, eliminating safety risks, time constraints, and operational complexities associated with transferring, loading/unloading, and aligning such large components across multiple workstations.

product name

TRT principal axis

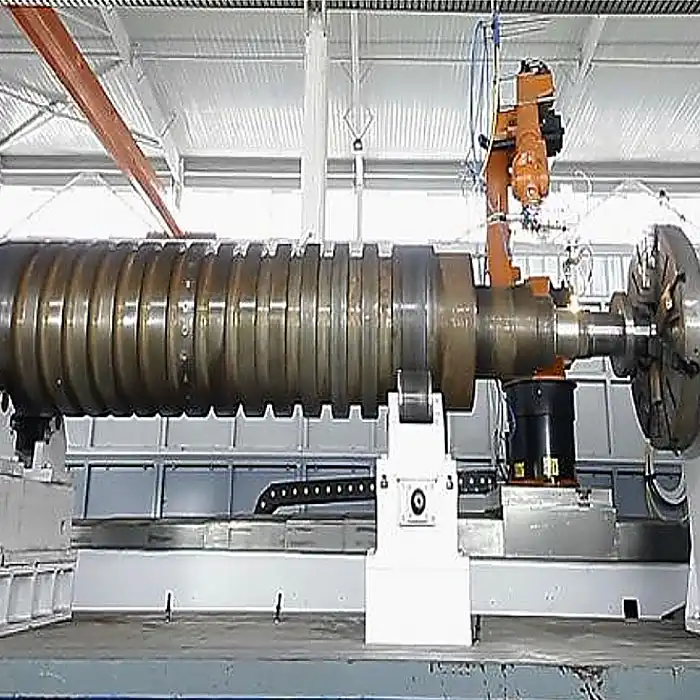

product picture

industry involved

Metallurgical industry

Associated Equipment

Power Generation Device of Blast Furnace Gas Residual Pressure Recovery

product process

High-speed Laser Cladding

Process materials

Special wear-resistant alloy

product property

Restore original size in the same material