TN-6000-Mobile robot laser cladding equipment

l Additive repair and printing of large workpieces

l Enable additive and subtractive manufacturing

- Product Description

Mobile robot laser cladding equipment

TN-6000

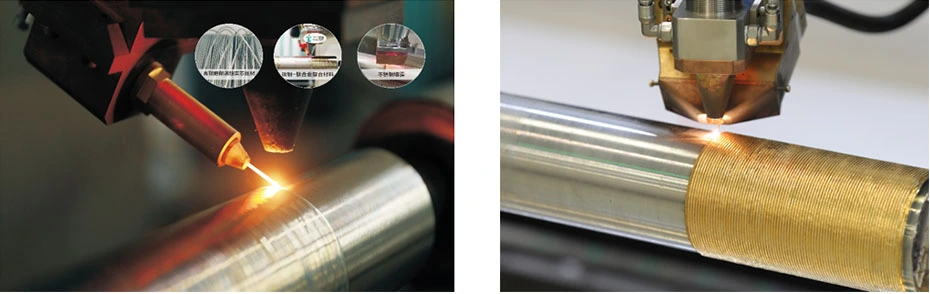

1. product picture

2. product use

The TN-6000 mobile robot laser cladding equipment is suitable for large plant areas, on-site repair of large workpieces, additive processing, and combined with subtractive machine tools to achieve integrated processing of materials.

l Additive repair and printing of large workpieces

l Enable additive and subtractive manufacturing

3. How it works

The composite additive manufacturing technology applied in the TN-6000 mobile robotic laser cladding system is centered on Directed Energy Deposition (DED). This cutting-edge DED technology utilizes laser beams or other energy sources to deposit metal powders layer by layer onto substrates, enabling the repair, reinforcement, or fabrication of three-dimensional components. It supports simultaneous additive and subtractive manufacturing processes, representing an advanced DED additive manufacturing approach that integrates multiple processes and material types.

l Process composite: laser and other forms of energy composite to improve efficiency and quality.

l Material composite: Different types of material composite additive can improve the surface properties of parts.

▲ metal dust ▲

4. Product Advantages

l Equipped with tracked self-propelled chassis: high passability through complex terrain, flexible operation;

l Combined with industrial 6-axis robot, it can carry out continuous automation operation;

l Modular design: highly integrated, mobile and flexible, can work across the factory and work stations.

l Contour surface: For complex parts, it features contour surface printing

l Automatic programming: Software automatically replaces manual programming

l It can be combined with subtractive machine tools to build an integrated processing mode of additive and subtractive materials

l Applicable to a variety of materials: can be applied to self-developed twisted wire, high strength welding wire, TIG welding wire, etc., including all kinds of carbon steel, stainless steel, nickel-based, cobalt-based alloy welding wire.

5. Device Parameters

order number | unit type | parameter |

1 | laser power | 6000W |

2 | Cladding method | Ring powder laser cladding |

3 | Exhibition of robotic arms | ≤1812mm |

4 | Length of cladding workpiece | ≤1600mm |

5 | Walk | DC motor drive |

6 | Mobile control method | Wired remote control |

7 | speed of travel | ≤1.5km/h |

8 | Tire platform endurance | 2H |

6 | supply electricity | Track vehicle (quick plug-in charging, automatic movement); laser cladding System (AirPort) |

10 | weight of equipment | ≈2T |

11 | Device transportation method | Forklift & truck handling |

12 | Device size (mm) | ≈1800*1340*2700 |