- Product Description

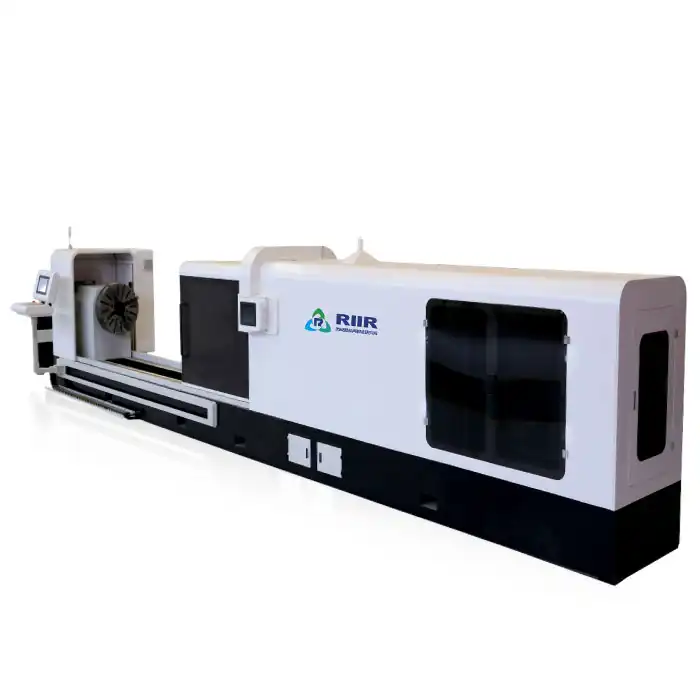

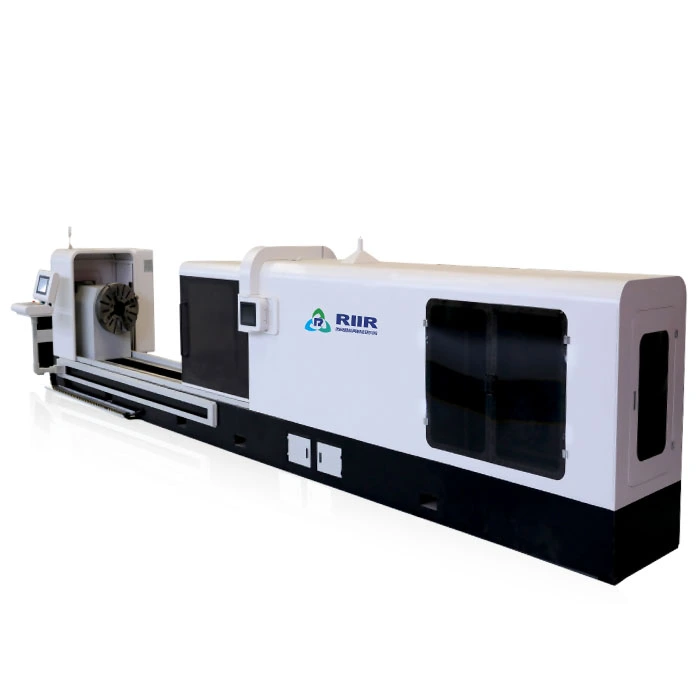

Internal and external wall cladding machine

JRN-1230F1

1. product picture

2. product use

The JRN-1230F1 integrated inner-outer wall cladding machine is designed for repairing and processing the inner and outer surfaces of various hydraulic cylinders and pipeline components.

l Additive manufacturing of hydraulic cylinder components

l Additive manufacturing of pipeline components

3. How it works

The JRN-1230F1-Integrated Internal/External Wall Cladding Machine employs composite additive manufacturing technology based on Directed Energy Deposition (DED). This cutting-edge DED process utilizes laser beams or other energy sources to melt metal powders, enabling layer-by-layer deposition on substrates for structural reinforcement or 3D part fabrication. The system supports simultaneous additive and subtractive manufacturing, representing an advanced DED technology that integrates multiple processes and material types.

l Process composite: laser and other forms of energy composite to improve efficiency and quality.

l Material composite: Different types of material composite additive can improve the surface properties of parts.

▲ metal dust ▲

4. Product Advantages

l Dual-purpose machine: Suitable for both inner-hole and outer-wall components, blind-hole and through-hole parts, as well as new parts reinforcement and old parts repair.

l High efficiency | Superior cladding quality: Cladding efficiency reaches 0.25-0.7㎡/h; single-layer cladding thickness adjustable within 0.5-2.0mm range; leading industry standards in density, hardness, and corrosion resistance.

l Patented laser cladding head design: It can meet the requirements of part root cladding and reduce the harm of reflection. The laser head is integrated with temperature measurement chip, height control chip and collision warning chip to ensure the stable, continuous and safe operation of the equipment.

l Human-machine interaction | Easy operation: Equipped with a visual process setup interface and handheld wireless remote control for simple and user-friendly operation. Built-in camera enables real-time observation of the cladding process on the inner wall of the borehole to ensure cladding quality.

l Versatile material compatibility: Suitable for melt coating of various materials including carbon steel, stainless steel, nickel-based and cobalt-based alloys.

l Easy to operate: Highly automated with built-in parameter algorithms and process packages, one-click invocation

5. Device Parameters

order number | unit type | parameter |

1 | Maximum load (kg) | 3000 |

2 | laser power (w) | 12000 |

3 | Maximum turning diameter (mm) | 800 |

4 | Coating length of exterior wall workpiece (mm) | 0-3000 |

5 | Melting diameter range (mm) | Φ60-φ500 |

6 | R-axis rotation speed (rpm) | 0-100 |

7 | X-axis speed (m/min) | 0-4 |

8 | Z-axis speed (m/min) | 0-3 |

9 | Spindle clamping method | 500mm three-jaw chuck (with front and rear jaws) + Ф60 straight shank center; the tailstock is equipped with a Morse 5# rotary center, featuring a center sleeve with a diameter of φ75mm and a stroke of 150mm. |

10 | Rear axle movement | Electric movement, manual clamping |

11 | Total equipment weight (T) | No more than 5 |

12 | Device transportation method | Forklift & truck handling |