- Product Description

Eight-axis conformal additive intelligent manufacturing machine

JRB-E606F2

1. product picture

2. product use

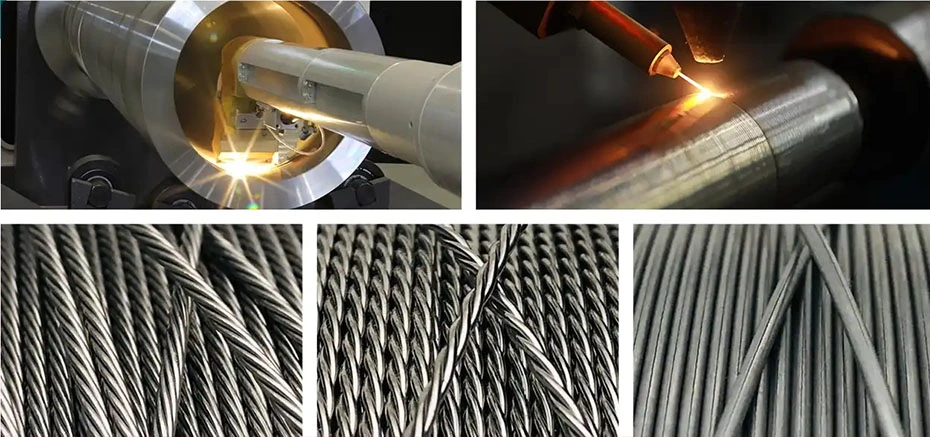

The JRB-E606F2 eight-axis conformal additive manufacturing system is designed for intelligent processing of shafts, flat surfaces, spherical components, and complex curved surfaces, enabling additive strengthening, repair, and printing.

l Additive manufacturing for shaft components

l Additive manufacturing of flat parts

l Add spherical parts

l Additive manufacturing of complex curved parts

3. How it works

The JRB-E606F2 eight-axis conformal additive manufacturing system employs composite additive manufacturing technology, with directional energy deposition (DED) as its core. This technology utilizes energy sources like laser beams to melt metal wires or powders, enabling layer-by-layer deposition on substrates for structural reinforcement or 3D part fabrication. Capable of simultaneous material addition and removal, it represents an advanced DED additive manufacturing approach that integrates multiple processes and material types.

l Process composite: laser and other forms of energy composite to improve efficiency and quality.

l Material composite: Different types of material composite additive can improve the surface properties of parts.

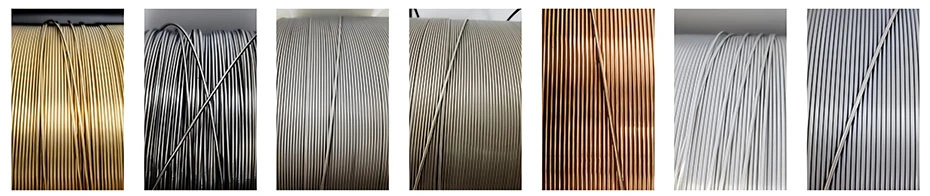

▲ metal wire ▲

▲ metal dust ▲

4. Product Advantages

l Intelligent additive manufacturing: Intelligent industrial control system reduces the difficulty of personnel operation, making additive intelligent and automated.

l High additive efficiency: the same delivery of wire and powder can improve the additive efficiency while ensuring the performance of the workpiece.

l Preparation of functional gradient material: the preparation of functional gradient material can be achieved by controlling the composite ratio of wire powder.

l Adapted to a wide range of materials: stainless steel, copper alloy, nickel-based alloy, cobalt-based alloy, titanium alloy and other materials can be coated.

l Compatible with wire/powder/combined wire-powder: The equipment is equipped with wire and powder interfaces, and can be equipped with corresponding material processing methods according to requirements.

l Large size: suitable for additive manufacturing and repair of complex structural parts within 600mm, with high flexibility and large movement size.

l High integration: All supporting modules are fully integrated into a single device framework.

5. Device Parameters

order number | project | parameter |

1 | outline dimension | 4100mm×2740mm×2500mm(W×D×H) |

2 | Forming dimensions | Φ600mm×600mm |

3 | laser power | 6000W multimode fiber laser |

4 | Laser cladding head | Central wire feed laser head / coaxial powder feed laser head / wire-powder hybrid laser head (optional) |

5 | High precision material conveying system | The metal constant-current disc feeder delivers powder with repeatability of ±2%, particle size 20-200μm, and speed 0-8 rpm. The wire feeding system features a push-type mechanism with wire speed adjustable from 0 to 100mm/s. |

6 | Motion Actuator | 6-axis robot + 2-axis positioner |

7 | coolant passage | Dual temperature control provides cooling water for the laser and external optical path |

8 | Materials Support | Various carbon steel, stainless steel, nickel-based, cobalt-based alloy materials; |

9 | power rating | 40kW |

10 | Power Supply Requirements | 380V±10%,50Hz |

_1762417930266.webp)