- Product Description

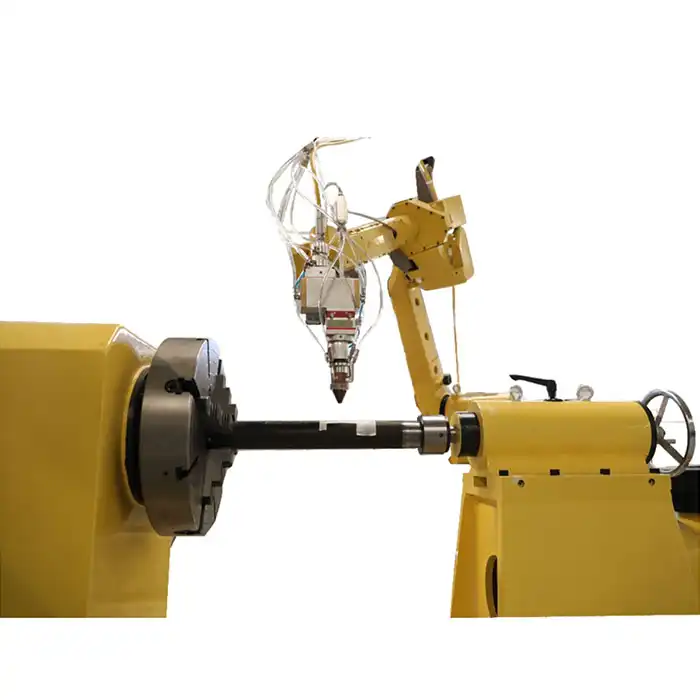

Robot laser conformal surface printing workstation

JRB-630F2 S1

1. product picture

2. product use

The JRB-630F2 S1-robotic laser conformal surface printing workstation is suitable for additive strengthening and repair of products such as shafts, planes, spheres, and complex curved surfaces, as well as for material development and process development in universities.

l Additive manufacturing for shaft components

l Additive manufacturing of flat parts

l Add spherical parts

l Additive manufacturing of complex curved parts

3. How it works

The JRB-630F2 S1-robotic laser conformal surface printing workstation employs composite additive manufacturing technology based on Directed Energy Deposition (DED). This cutting-edge DED technology utilizes laser beams or other energy sources to melt metal wires or powders, enabling layer-by-layer deposition on substrates for repairing, reinforcing, or creating 3D components. The system supports simultaneous additive and subtractive manufacturing processes, representing an advanced DED technology that integrates multiple manufacturing techniques and material types.

l Process composite: laser and other forms of energy composite to improve efficiency and quality.

l Material composite: Different types of material composite additive can improve the surface properties of parts.

▲ metal wire ▲

▲ metal dust ▲

4. Product Advantages

l Contour surface: For complex parts, it features contour surface printing

l Automatic programming: Software automatically replaces manual programming

l Equipped with industrial 6-axis robot and turntable: with 7-axis linkage function, it can realize rapid surface strengthening of shaft parts

l Expandable dual-axis positioner: Suitable for multi-functional and multi-scenario machining needs

l Versatile material compatibility: Suitable for melt coating of various materials including carbon steel, stainless steel, nickel-based and cobalt-based alloys.

5. Device Parameters

unit type | JRB-630F2/S1 | ||

Forming technology | LENS laser near-net-shape forming technology | Gas support | Ar、N₂ |

Print features | Software with features for surface printing and complex parts Automate programming instead of manual | Tool magazine capacity | Replaceable, multifunctional print head |

Materials Support | Various carbon steel, stainless steel, nickel-based and cobalt-based alloy materials | Cladding speed | The linear speed can reach 1100mm/s, depending on the complexity of the part And change |

powder feeder | Metal constant flow powder feeder | Forming dimensions | Maximum print length (X): 4000mm Maximum turning diameter R(Z): 1000mm Y-axis travel (Y): ±1000mm |

lift height | 0.5mm-2.0mm Continuous adjustment | Additive Axis | 6+2 axis |

Print Precision | Repeatability: ≤0.06mm | navar | Self-developed ProAM3D printing control system |

Construction speed | 0-5kg/h | Supplementary software | Self-developed ProLC automatic programming software |

Work oxygen level | Local inert gas protection of the melt pool | foot platform Maximum load | Maximum load: 5000kg Supports workpiece with a maximum clamping diameter of 600mm Supports maximum workpiece load length: 3000mm |