- Product Description

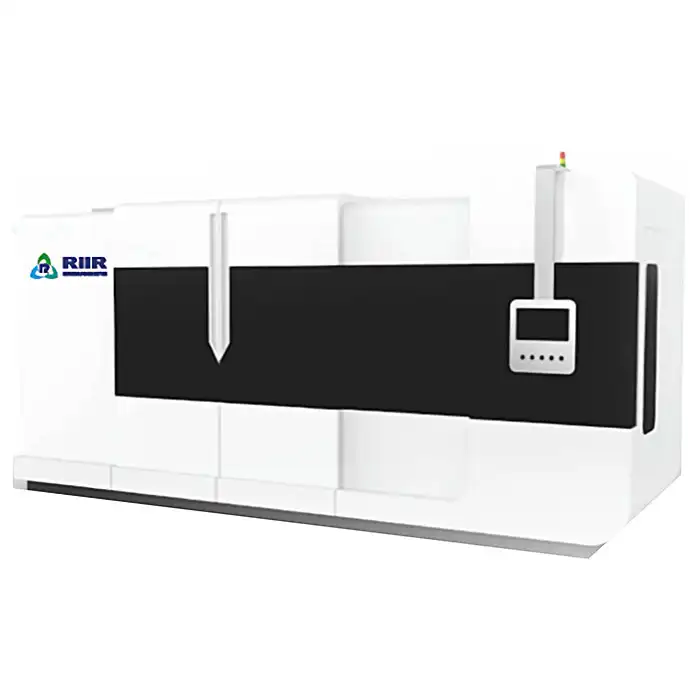

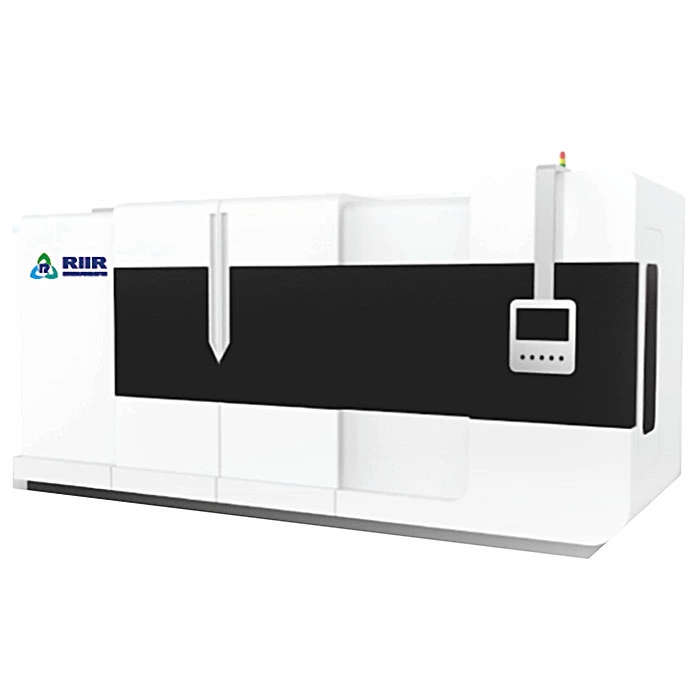

High speed wire-powder composite laser cladding equipment

JRA-630F1

1. product picture

2. product use

The JRA-630F1 high-speed wire-powder hybrid laser cladding system is designed for anti-corrosion and wear-resistant reinforcement of internal and external surfaces on shafts, hydraulic cylinders, pipelines, and similar components.

l Additive manufacturing for shaft components

l Additive manufacturing of hydraulic cylinder parts

l Additive manufacturing of pipe components

3. How it works

The JRA-630F1 high-speed wire-powder composite laser cladding system employs additive manufacturing technology based on Directed Energy Deposition (DED). This cutting-edge DED process utilizes laser beams or other energy sources to melt metal wires or powders, enabling layer-by-layer deposition on substrates for structural reinforcement or 3D part fabrication. The system supports simultaneous additive and subtractive manufacturing, representing an advanced DED technology that integrates multiple processes and material types.

l Process composite: laser and other forms of energy composite to improve efficiency and quality.

l Material composite: Different types of material composite additive can improve the surface properties of parts.

▲ metal wire ▲

▲ metal dust ▲

4. Product Advantages

l Low thermal input: The low thermal input further reduces the deformation of the laser cladding process, which can be used to remanufacture slender shaft parts such as small cylinder piston rods

l High cladding efficiency: Under the same laser power, the cladding efficiency can be more than twice that of powder laser cladding technology

l Excellent mechanical properties: The laser cladding layer on the wire material is dense and defect-free, with superior mechanical properties. It restores both the size and strength of the part.

l High material utilization rate: the material utilization rate is more than 99%, reducing material waste

l Versatile material compatibility: Suitable for cladding processing of various materials including stainless steel, copper alloys, nickel-based alloys, cobalt-based alloys, and titanium alloys.

l Good environmental protection: because of the use of silk material, the cladding process has no dust splashing, good environmental protection

l Easy to operate: Highly automated with built-in parameter algorithms and process packages, one-click invocation

5. Device Parameters

order number | unit type | parameter |

1 | Maximum load (kg) | 3000 |

2 | laser power (w) | 6000 |

3 | Maximum turning diameter (mm) | 800 |

4 | Coating length of exterior wall workpiece (mm) | 0-3000 |

5 | Melting diameter range (mm) | Φ60-φ500 |

6 | R-axis rotation speed (rpm) | 0-100 |

7 | X-axis speed (m/min) | 0-4 |

8 | Z-axis speed (m/min) | 0-3 |

9 | Spindle clamping method | 500mm three-jaw chuck (with front and rear jaws) + φ60 straight shank center; the tailstock is equipped with Morse 5# rotary center, featuring a 75mm diameter center sleeve with a 150mm stroke. |

10 | Rear axle movement | Electric movement, manual clamping |

11 | Total equipment weight (T) | No more than 5 |

12 | Device transportation method | Forklift & truck handling |